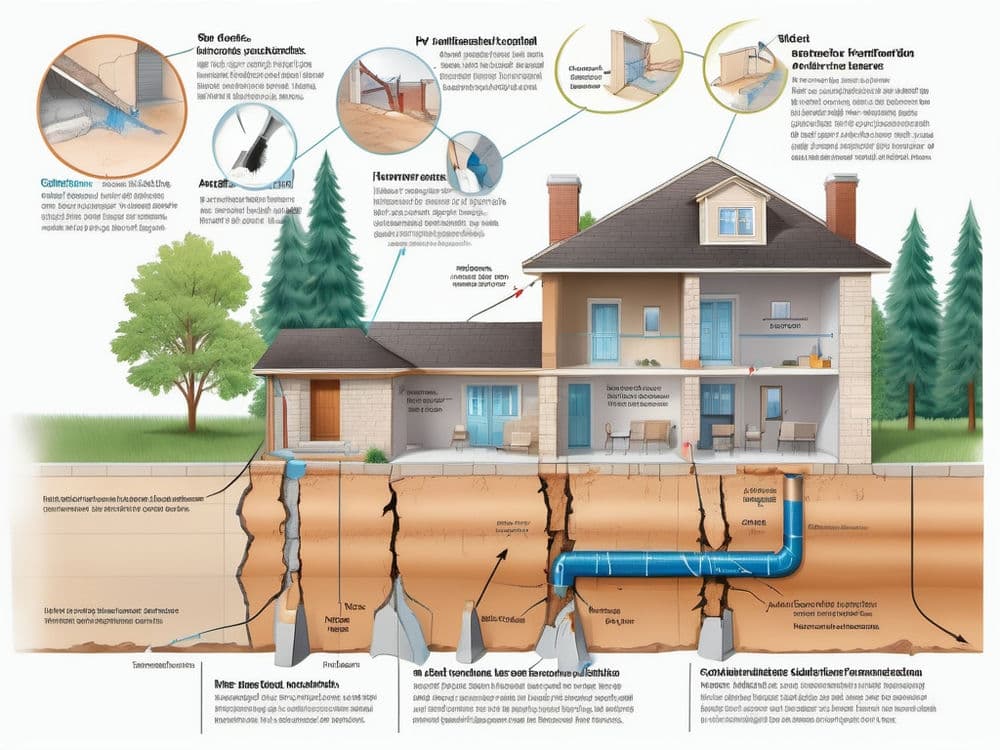

Helical pile installation represents a major shift in foundation engineering, providing a cost-effective and efficient solution for both commercial and residential structures. This technology, which echoes the basic principles of geotechnical engineering has revolutionized the way we approach foundation stability, especially when soil conditions are difficult.

They provide a durable foundation that lasts for a long time Advancing Construction Technology with Helical Piles economics. They provide strong, stable support and are resistant to shifting and settling helical piles installation pitch.The design of helical piles combines the mechanics of screw threads as well as the geometry of helix, making them ideal for piercing different soil kinds. The components, constructed from robust materials like steel, exhibit outstanding tensile strength and durability. Their unique design minimizes ground disturbance, a feature that is particularly useful in areas that are environmentally sensitive.

One of the main elements of helical pile installation is to achieve the desired load capacity. This is when the relationship between installation torque and load capacity is crucial. The most modern torque gauges, such as those from Chance Digital Torque Indicator, play a pivotal role in this process, offering accurate measurements, and removing the uncertainty that are associated with estimates of pressure in hydraulic systems.

The speed of operation during installation is vital, generally being between 8 and 16 RPM. This controlled speed makes sure that the pile is moving about 3 inches every revolution consistent with the pitch of the helical plates. If the pile isn't moving as expected, adjustments like raising downward thrust or adding larger plates for helicals are made to prevent'spinning out' like a screw ripping its threads.

Screw Piles Market Size to be Worth USD 1.56 billion by 2031, at a CAGR of 5.5 %| Transparency Market Research, Inc. GlobeNewswire

Posted by on 2024-01-03

Grand Forks begins multi-year expansion of wastewater treatment plant Grand Forks Herald

Posted by on 2023-11-06

VersaPile a versatile helical steel pile contractor in Manitoba - constructconnect.com Daily Commercial News

Posted by on 2023-10-02

DFI Announces Recipients of the 2023 Legends Awards Tunneling Business Magazine

Posted by on 2023-09-06

What Are Helical Piles Used For - Make It Right® Mike Holmes

Posted by on 2023-08-03

Volusia homeowners install piles as retention pond threatens foundations WKMG News 6 & ClickOrlando

Posted by on 2023-07-11

Transmission Construction: Micropile-Grillage Base Works in Virginia's Mountains T&D World

Posted by on 2023-05-31

Helical piles can speed up a home renovation National Post

Posted by on 2023-04-25

One of the primary benefits of the helical piles is their quick installation. Unlike traditional foundations, which usually require a significant excavation and curing for concrete, helical piles are placed directly into the ground. This is not just faster but also less disruptive to the surroundings. It reduces the duration of construction, allowing projects to move forward faster.

Helical piles, also referred as screw piles a kind of foundation that is deep and consists from a shaft central and one or more blades that resemble helix shapes. The design permits them to be screwed into the ground, creating an extremely solid and safe foundation for different types of structures. Originating from the 19th-century innovations from Irish engineer Alexander Mitchell, helical piles have advanced and are in the forefront of contemporary foundation technology.

One of the most notable features of helical piles is their speed and ease of installation. In contrast to traditional concrete foundations which require extensive excavation and curing time they are able to be installed quickly using hydraulic machinery. This not only accelerates the process of construction but also minimizes any impact to the surrounding natural environment. The reduced need for large excavation areas makes them particularly useful in urban settings or in environmentally sensitive zones where preserving the natural landscape is crucial.

Alongside their main benefits, helical piles are also equipped with other advantageous features that further solidify their position in modern construction. They include:

These additional advantages, when combined with their primary advantages are what make helical piles a highly versatile and reliable foundation choice for a variety of construction projects.

It is the most important attribute of Helical piles. They can be adapted to a range of soil types and conditions, making an ideal choice for a range of projects, ranging from residential structures to industrial structures. Their design is able to be modified to meet the specific requirements of load, enhancing their applicability across various types of construction.

Helical piles also offer the benefit of instant load-bearing capacity.

The sustainability aspect of helical piles cannot be overlooked. They are often made from recycled steel and are dismantleable, allowing reuse in future projects. This reuse, along with the lower carbon footprint in the process of installation is in line with the increasing emphasis on green construction practices.

In the end, the hidden strengths of the installation of helical piles - speed, minimal environmental impact, flexibility in load capacity and speed of installation, and their sustainability - account for their growing popularity in the construction field. As we continue to search the most efficient, economical, and sustainable building techniques Helical piles are a strong, innovative solution for modern construction challenges.

Based on the strength and foundation of the helical piles Their usage in construction projects provides several advantages. These are as follows:

These issues highlight the multiple benefits of the use of helical piles, emphasizing their role in improving efficiency, sustainability and cost-effectiveness of construction.